As we head into the colder season here in Alberta, and all of Canada, the concrete business definitely slows down substantially, but we don’t have to stop completely. Working with concrete becomes much more difficult in the winter but there are plenty of different techniques that we can use to make things go smoother. In this post we are going to go over some helpful reminders and provide some excellent resources to help you keep going with your projects through the winter.

Concrete Alberta: Cold Weather Reminders

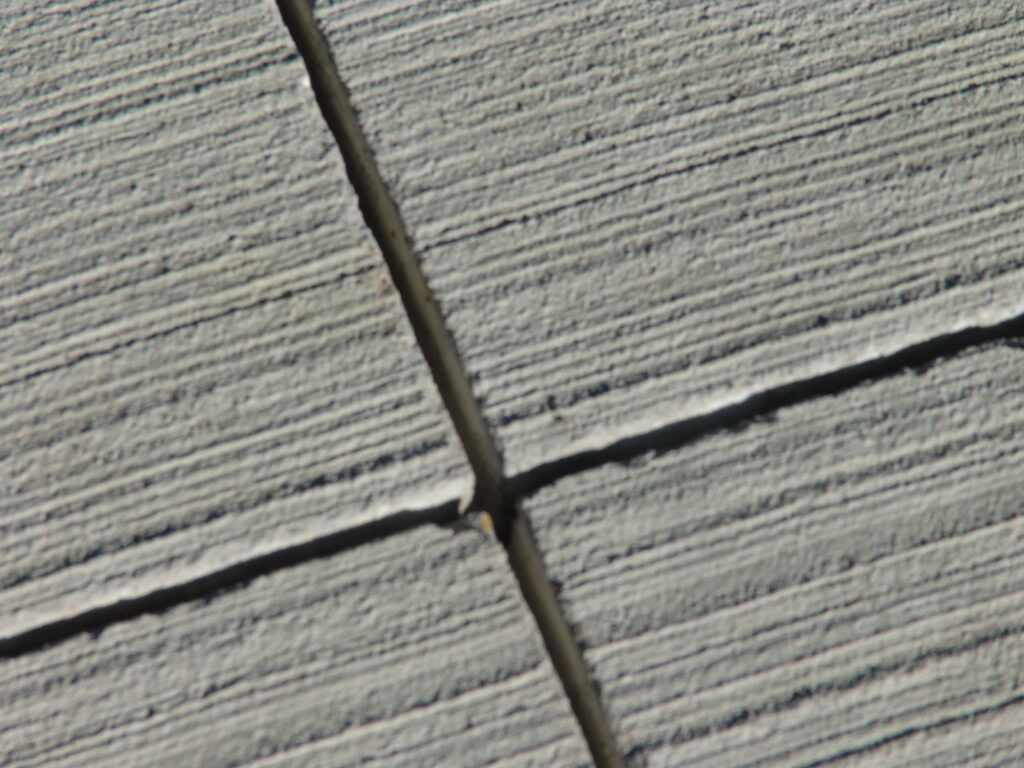

Concrete Alberta is a great resource that many industry professionals use. The linked article here has some great tips and reminders about working with concrete in the winter. Some of the things mentioned in this article are. Using low water content and air entrained concrete as it is delivered. If you are expecting freezing temperatures than you do not want as much water in the mix as it will cause plastic shrinkage, see our article on Why Concrete Cracks to learn more about why cracks form in concrete and how you can prevent and fix it. Another point made by Concrete Alberta is ensuring you allow adequate time for curing as especially in low temperatures concrete can take more than 28 days to achieve 70% strength.

Concrete Alberta: Cold Weather Concrete Practices

Another document from Concrete Alberta, this one is one is about pouring walls and foundation in cold weather. Again we are just going to lightly go over a few of the key points made in the article but the full write-up will be linked here.

Concrete Alberta talks about the importance of excavation and site preparation. It is best to look at the forecast ahead of time and ensure that the ground won’t be frozen or covered in snow when you are pouring. If the ground is frozen or snow is forecasted, covering the ground with tarps or insulation barriers is a good idea and even using heaters can work, however preventative measures are better than reactive ones.