Concrete is a remarkable material known for its strength and durability. However, despite its robust nature, concrete can develop cracks over time, causing concerns for homeowners and contractors alike.In this article, we will explore why concrete cracks and provide valuable insights into preventing and fixing these issues. By understanding the causes and implementing appropriate measures, you can ensure the longevity and structural integrity of your concrete projects.

Causes of Concrete Cracks

Plastic Shrinkage

During the early stages of concrete curing, rapid moisture evaporation can cause plastic shrinkage cracks. These typically appear as shallow cracks on the surface and are influenced by factors such as high temperatures, low humidity, and wind.

As concrete dries and hardens, it undergoes shrinkage due to the loss of moisture. This can lead to drying shrinkage cracks, which are commonly observed in large concrete slabs or structures. Insufficient control joints or improper mix proportions can exacerbate this issue.

Thermal Effects

Extreme temperature variations, especially in regions with significant temperature fluctuations, can induce thermal stresses in concrete. These stresses result in thermal expansion or contraction, leading to cracks. Freezing and thawing cycles are also culprits, causing concrete to crack over time.

Structural Overload

Excessive loads beyond the capacity of the concrete can cause cracks to develop. This may occur due to heavy vehicles, inadequate reinforcement, or poor design choices, compromising the structural integrity of the concrete.

Preventive Measures

Proper Mix Design

Ensure that the concrete mix is designed appropriately for the intended application. Use quality materials, maintain the correct water-cement ratio, and consider adding admixtures to improve durability and reduce shrinkage. We offer many different mixes with different admixtures available that will help your concrete suit the job you are doing and ensure you end up with the product you want.

Reinforcement

Reinforcing concrete with steel or fiberglass rebar, wire mesh, or fiber reinforcement helps control crack formation and enhances structural strength. Reinforcement distributes loads and provides resistance against cracking caused by shrinkage or external forces.

Control Joints

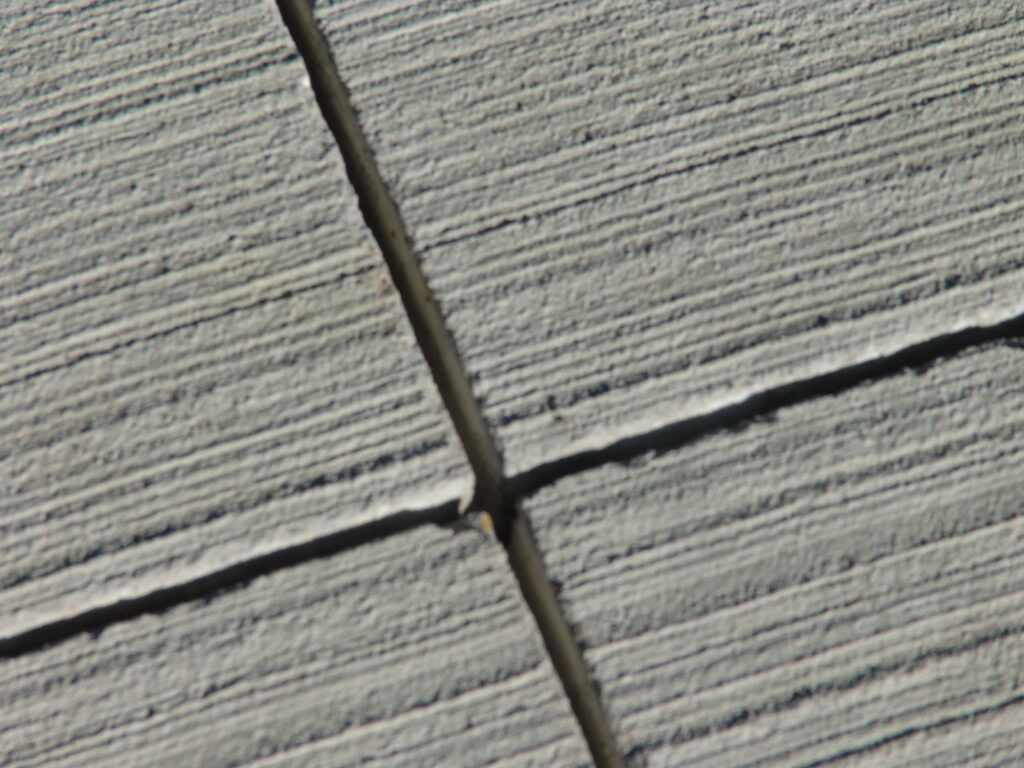

Concrete saw used for making cuts that allow the concrete to crack in a controlled manner

Strategically placed control joints allow for controlled cracking at specific locations, relieving stress and preventing random crack formation. Consult with a professional engineer to determine the correct spacing and depth of control joints based on your project’s requirements.

Curing Techniques

Keeping a light layer of water over a concrete pad while it is curing will ensure that the concrete will not run out of moisture, leading to drying shrinkage

Proper curing is crucial to mitigate plastic and drying shrinkage cracks. Use curing compounds, plastic sheets, or wet curing methods to maintain adequate moisture levels during the concrete’s initial stages. This promotes hydration and minimizes shrinkage.

Conclusion

Understanding why concrete cracks and implementing preventive measures is essential for maintaining the longevity and aesthetics of your concrete projects. By incorporating proper mix design, reinforcement, control joints, and effective curing techniques, you can minimize the occurrence of cracks. Additionally, promptly addressing any cracks through suitable repair methods will prevent further deterioration and extend the lifespan of your concrete structures. Remember, when it comes to concrete cracks, your best offense is a good defense.